Hydraulic systems rely on precise fittings to securely connect components and maintain fluid flow under high pressure. The right hydraulic fitting can prevent leaks, enhance system efficiency, and ensure the longevity of the equipment. At Hoson, we specialize in producing a broad range of hydraulic fittings and components, from SAE adapters and metric thread adapters to specialized fittings in stainless steel, brass, and aluminum. This article explores the main types of hydraulic fittings and explains how to choose the right one for your hydraulic system.

Why Hydraulic Fitting Types Matter

The choice of hydraulic fitting impacts a system’s reliability, performance, and safety. Different fitting types are designed to address specific needs, from ensuring a leak-proof seal to fitting within space constraints. Understanding the differences between hydraulic fitting types can help you make informed decisions when selecting the most suitable options for your application.

1. SAE (Society of Automotive Engineers) Adapters

SAE adapters are designed to meet strict SAE standards and are commonly used in industrial and automotive hydraulic systems.

Standardization: SAE fittings follow a standardized size and thread type, making them widely compatible with various hydraulic systems.

Thread Types: SAE fittings commonly use straight or tapered threads, which are chosen depending on the pressure requirements. They offer a reliable seal with the use of O-rings or tapered threads.

Applications: These fittings are widely used in automotive, industrial machinery, and agricultural equipment. Their reliability and availability make them a versatile choice for many applications.

2. Inch Thread Adapters

Inch thread adapters are specified in inch measurements and are commonly found in systems following American standards.

Unified Thread Standard (UTS): Inch-threaded fittings often follow UTS specifications, which are commonly used in North American systems.

Compatibility: Inch thread adapters are designed to fit with equipment or systems that also follow inch measurement standards, allowing for seamless integration in such systems.

Applications: Commonly found in older machinery and systems, inch thread adapters are useful in industries that rely on North American standards for their hydraulic systems.

3. Metric Thread Adapters

Metric thread adapters are commonly used in hydraulic systems that adhere to international standards and are prevalent in European and Asian equipment.

Metric Standards: These fittings follow metric thread specifications, often based on ISO standards, which offer a broad range of sizes and thread pitches.

Pressure Ratings: Metric adapters can handle various pressure ranges, making them suitable for both low and high-pressure applications.

Applications: Metric thread adapters are frequently used in equipment and machinery manufactured outside North America, including heavy equipment, automotive, and industrial machinery.

4. Standard Hose Fittings

Standard hose fittings are designed to securely connect hoses in hydraulic systems, allowing fluid to flow between different system components.

Types of Connections: Hose fittings come in various connection types, such as crimped, reusable, and push-to-connect, allowing for flexibility based on application needs.

Material Options: Hoson produces standard hose fittings in materials like stainless steel, brass, and aluminum, providing corrosion resistance and durability for different environmental conditions.

Applications: Hose fittings are commonly used in mobile and industrial hydraulic systems, where hoses play a critical role in fluid transfer and system mobility.

5. Ferrules

Ferrules are essential components for connecting hoses to fittings securely and preventing leaks, especially in high-pressure applications.

Reinforcement and Leak Prevention: Ferrules provide extra reinforcement at the connection point, creating a tighter seal between the hose and the fitting.

Types of Ferrules: Ferrules can be made from materials like stainless steel or brass, and come in crimped or swaged versions depending on the pressure and flexibility requirements.

Applications: Commonly used in high-pressure applications where hose integrity is crucial, ferrules are ideal for industries like construction, agriculture, and mining.

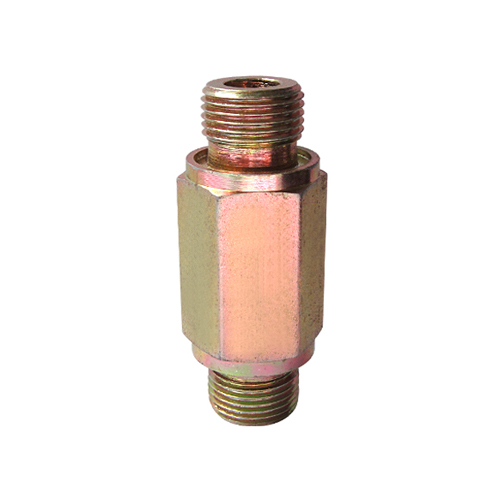

6. Nuts and Oil Plugs

Nuts and oil plugs play a critical role in sealing and securing connections within hydraulic systems, preventing fluid leakage and ensuring system integrity.

Sealing Capabilities: Nuts and oil plugs are designed to create a leak-proof seal in various parts of the hydraulic system, maintaining fluid pressure.

Materials and Coatings: These components are often made from corrosion-resistant materials such as stainless steel, brass, or coated steel, extending the lifespan of the fittings.

Applications: Nuts and oil plugs are commonly used in hydraulic systems where oil or fluid needs to be securely contained, such as in hydraulic reservoirs, pumps, and gear systems.

7. Specialized Adapters (Stainless Steel, Brass, Aluminum)

Specialized adapters in materials like stainless steel, brass, and aluminum offer unique properties that make them suitable for specific applications and environmental conditions.

Stainless Steel Adapters: Known for their corrosion resistance, stainless steel adapters are ideal for environments exposed to moisture or chemicals, such as marine or chemical processing applications.

Brass Adapters: Brass is durable, corrosion-resistant, and non-sparking, making it suitable for sensitive applications, such as in the gas and oil industries.

Aluminum Adapters: Lightweight and resistant to corrosion, aluminum adapters are often used in applications where weight savings are important, such as in aerospace and automotive sectors.

How to Choose the Right Hydraulic Fitting

Selecting the right hydraulic fitting depends on several factors, including pressure rating, compatibility, environmental conditions, and application requirements. Here’s a quick guide to help you make the right choice:

Consider Pressure Requirements: High-pressure systems require fittings designed to handle the pressure without leaking or failing. Ferrules and high-grade materials like stainless steel are often preferred for these applications.

Match Thread Standards: Determine if your system requires SAE, inch, or metric threads to ensure compatibility. Using incompatible thread standards can lead to leaks, system failures, or costly repairs.

Evaluate Material Needs: Choose materials based on environmental conditions. For instance, stainless steel fittings are excellent in corrosive environments, while aluminum is preferred for lightweight applications.

Assess Connection Type: For hoses, select the appropriate connection type based on your application. Crimped connections offer a secure fit for high-pressure applications, while push-to-connect fittings provide ease of use for lower-pressure systems.

Check for Non-Standard Needs: If your system requires custom specifications, look for suppliers like Hoson that can provide non-standard sizes and designs tailored to your unique requirements.

Hoson’s Commitment to Quality and Variety in Hydraulic Fittings

At Hoson, we understand that hydraulic systems vary widely, and each application demands specific fitting types for optimal performance. Our expertise in producing a broad range of hydraulic fittings allows us to provide clients with options that meet their exact specifications, whether they require standard or custom solutions. Our offerings include:

Extensive Range: From SAE, inch, and metric thread adapters to specialized hose fittings, ferrules, and non-standard components, Hoson offers solutions for a variety of industries and applications.

Custom Manufacturing: We provide custom fittings in unique sizes and configurations, enabling clients to address specific requirements in their hydraulic systems.

High-Quality Materials: Using durable materials like stainless steel, brass, and aluminum, we ensure that our fittings can withstand challenging environments, from high-pressure applications to corrosive conditions.

Final Thoughts

Understanding the different types of hydraulic fittings is essential for designing and maintaining efficient hydraulic systems. By choosing the right fitting type—whether it’s SAE adapters, metric thread adapters, hose fittings, or specialized adapters in stainless steel or brass—you can optimize your system’s performance, minimize leaks, and ensure long-term reliability. Hoson’s commitment to providing high-quality hydraulic fittings, combined with our expertise in both standard and custom components, makes us a trusted partner for all your hydraulic needs. Whether you’re building a new system or maintaining existing equipment, Hoson has the fitting solution to meet your requirements.