Hydraulic systems are the backbone of many industrial applications, from heavy machinery in construction to precision equipment in manufacturing. The integrity of these systems is crucial for ensuring efficiency, safety, and reliability. One of the key components in ensuring the performance and safety of hydraulic systems is the use of hydraulic test fittings. These fittings are vital for testing the pressure and performance of hydraulic systems, ensuring they operate at optimal levels without risking failure or damage. In this article, we explore the technical specifications, applications, and uses of hydraulic test fittings.

What Are Hydraulic Test Fittings?

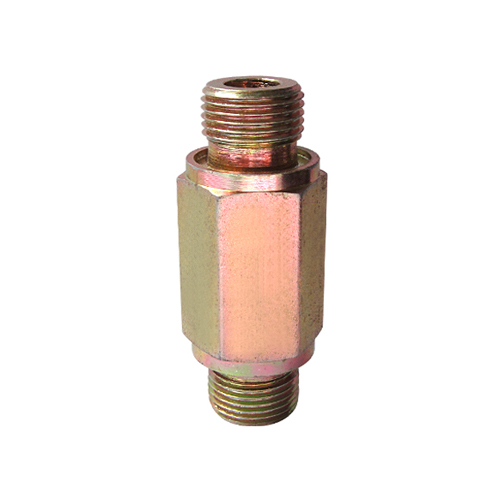

Hydraulic test fittings are specialized components used to test, monitor, and maintain the pressure levels within a hydraulic system. These fittings are designed to allow technicians to safely connect pressure gauges, sensors, and testing equipment to the hydraulic system without compromising the integrity of the system itself. They are commonly used during the initial setup, routine maintenance, and troubleshooting of hydraulic equipment.

Hydraulic test fittings are typically installed in critical areas of the system where pressure measurement is necessary, such as the inlet or outlet of a pump, cylinder, or valve. They play a crucial role in preventing over-pressurization, monitoring system health, and verifying operational efficiency. These fittings ensure that the hydraulic system operates within the manufacturer's recommended pressure range, preventing costly damage or downtime.

Technical Specifications of Hydraulic Test Fittings

Hydraulic test fittings are designed to withstand high-pressure environments while providing secure connections for test equipment. Key technical specifications to consider when selecting hydraulic test fittings include:

Pressure Rating:

The pressure rating of hydraulic test fittings is one of the most important specifications to consider. These fittings must be able to handle the maximum pressure the hydraulic system will experience. Pressure ratings for test fittings can vary widely, with fittings designed for low-pressure systems starting at 1,000 psi and high-pressure systems reaching up to 10,000 psi or more. The choice of pressure rating depends on the application and the requirements of the hydraulic system.Material:

Hydraulic test fittings are typically made from high-strength materials that can resist corrosion and wear under extreme pressure. Common materials include:Steel: The most commonly used material for hydraulic fittings due to its strength and ability to withstand high-pressure conditions.

Stainless Steel: Preferred for applications where corrosion resistance is critical, such as in marine or chemical industries.

Brass and Aluminum: Used for lighter-duty systems or where cost is a concern, although these materials may not be suitable for the highest pressure environments.

Connection Type:

The connection type of hydraulic test fittings can vary depending on the application. Common connection types include:Threaded: The most common type, featuring standard threads (e.g., NPT, BSP, SAE) to connect with other components.

Flanged: Used when a more secure, high-pressure connection is required.

Quick-Connect: Ideal for systems that require frequent disconnects for testing or maintenance purposes, allowing for faster setup and teardown.

Size:

Hydraulic test fittings come in various sizes to accommodate different hose and pipe diameters. The size must match the hydraulic system’s design to ensure a secure connection and accurate pressure readings. Sizes typically range from 1/8 inch to several inches in diameter, depending on the flow rate and pressure requirements of the system.Sealing Mechanism:

To prevent leaks and ensure the integrity of the system, hydraulic test fittings are designed with robust sealing mechanisms. These seals can include O-rings, gaskets, or metal-to-metal seals. The choice of sealing mechanism depends on the system’s pressure and fluid compatibility. For high-pressure systems, metal-to-metal seals are often preferred, while O-rings or gaskets may be suitable for lower-pressure applications.Temperature Resistance:

Depending on the application, hydraulic systems can operate under extreme temperatures. Hydraulic test fittings must be designed to handle a wide range of temperatures, from freezing conditions in cold climates to the elevated temperatures found in heavy machinery. Materials and seals used in the fittings must be chosen to withstand these temperature extremes.

Common Uses of Hydraulic Test Fittings

Hydraulic test fittings are used in a wide range of industries and applications, where testing the hydraulic system is essential to ensuring safe and reliable operation. Below are some of the most common uses:

Pressure Testing:

One of the primary uses of hydraulic test fittings is for pressure testing. Before putting a new hydraulic system into operation, it's essential to verify that it can safely handle the required pressure. Test fittings are used to connect pressure gauges or transducers to the system, allowing technicians to measure the pressure and verify that it meets specifications.System Diagnostics and Troubleshooting:

Hydraulic test fittings are invaluable for diagnosing problems in hydraulic systems. If there are concerns about system performance, test fittings can be used to check for issues such as pressure drops, leaks, or irregular flow. Technicians can identify areas of concern without disassembling the entire system, allowing for quicker and more cost-effective repairs.Maintenance and Calibration:

Regular maintenance and calibration of hydraulic systems are necessary to ensure they remain efficient and safe. Test fittings are used during routine inspections to check for system performance, verify pressure levels, and calibrate instruments like pressure sensors and valves. Proper calibration ensures the system operates within the required pressure range, preventing premature wear and tear on components.Hydraulic Fluid Testing:

In addition to pressure testing, hydraulic test fittings are also used to check the quality of hydraulic fluid. Fittings allow for the safe extraction of fluid samples, which can be analyzed for contaminants or degradation. This is essential in maintaining the system’s efficiency and prolonging its lifespan.Safety Shutdown Systems:

In some applications, hydraulic systems are equipped with safety shutdown systems that automatically engage when pressure levels exceed safe thresholds. Test fittings are used to verify that these safety systems are calibrated correctly, ensuring that they will function when needed to prevent system failure or catastrophic damage.

Industry-Specific Applications

The versatility of hydraulic test fittings makes them essential across many industries. Here are a few examples of how they are used in specific sectors:

Automotive Industry:

In automotive manufacturing and testing, hydraulic test fittings are used to monitor and test hydraulic systems in vehicles, such as brakes, suspension systems, and steering mechanisms. Proper testing ensures vehicle safety and performance.Construction and Mining:

Hydraulic systems in construction and mining equipment must be tested regularly to ensure they can handle the extreme pressures associated with heavy machinery. Test fittings help to monitor and troubleshoot equipment such as excavators, bulldozers, and cranes, ensuring they operate reliably under demanding conditions.Oil and Gas Industry:

In the oil and gas industry, hydraulic systems are crucial for drilling, pumping, and extraction operations. Test fittings are used to verify the pressure and integrity of the hydraulic systems used in these operations, where failure can have catastrophic consequences.Aerospace:

Aerospace hydraulic systems require precise monitoring and testing. Test fittings are used to ensure that hydraulic components in aircraft, including landing gear and flight control systems, meet safety and performance standards.

Hoson’s Commitment to Quality and Innovation

At Hoson, we understand the importance of reliable and high-quality hydraulic test fittings. Our products are designed to meet the demanding specifications of various industries, ensuring safe and accurate pressure testing and system diagnostics. We offer a range of hydraulic test fittings made from premium materials to ensure durability, performance, and longevity in even the most challenging environments.

Whether you are working in construction, automotive, oil and gas, or aerospace, Hoson’s hydraulic test fittings are built to help you maintain the integrity of your hydraulic systems and improve operational efficiency.

Conclusion

Hydraulic test fittings play a critical role in ensuring the reliability, safety, and performance of hydraulic systems across a wide range of industries. By understanding their technical specifications and proper uses, businesses can ensure that their hydraulic systems operate efficiently and without failure. When selecting hydraulic test fittings, it's crucial to consider factors such as pressure rating, material, size, and connection type. Working with a trusted supplier like Hoson ensures that you get high-quality, durable fittings that meet the specific demands of your application, helping to keep your hydraulic systems running smoothly for years to come.